- 您现在的位置:买卖IC网 > Sheet目录39246 > LM2576D2TR4-12 (ON SEMICONDUCTOR) 7.5 A SWITCHING REGULATOR, 63 kHz SWITCHING FREQ-MAX, PSSO5

LM2576

http://onsemi.com

8

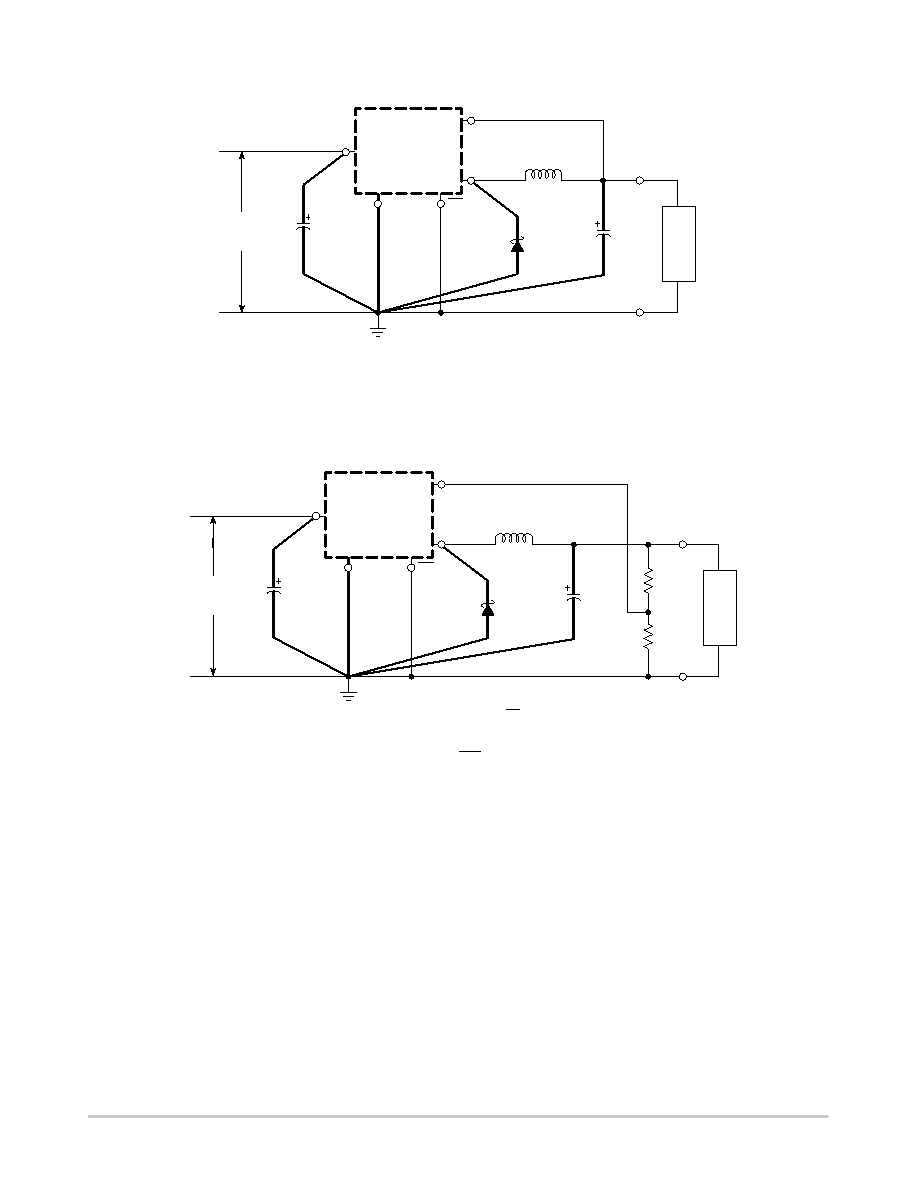

Figure 15. Typical Test Circuit

D1

MBR360

L1

100

mH

Output

2

4

Feedback

Cout

1000

mF

Cin

100

mF

LM2576

Fixed Output

1

5

3ON/OFF

GN

D

Vin

Load

Vout

D1

MBR360

L1

100

mH

Output

2

4

Feedback

Cout

1000

mF

Cin

100

mF

LM2576

Adjustable

1

5

3ON/OFF

GN

D

Vin

Load

Vout

5,000 V

Fixed Output Voltage Versions

Adjustable Output Voltage Versions

Vout + Vref 1.0 )

R2

R1

R2

+ R1

Vout

V

ref

– 1.0

Where Vref = 1.23 V, R1

between 1.0 k and 5.0 k

R2

R1

Cin

100

mF, 75 V, Aluminium Electrolytic

Cout

1000

mF, 25 V, Aluminium Electrolytic

D1

Schottky, MBR360

L1

100

mH, Pulse Eng. PE92108

R1

2.0 k, 0.1%

R2

6.12 k, 0.1%

7.0 V 40 V

Unregulated

DC Input

7.0 V 40 V

Unregulated

DC Input

PCB LAYOUT GUIDELINES

As in any switching regulator, the layout of the printed

circuit board is very important. Rapidly switching currents

associated with wiring inductance, stray capacitance and

parasitic inductance of the printed circuit board traces can

generate

voltage

transients

which

can

generate

electromagnetic interferences (EMI) and affect the desired

operation. As indicated in the Figure 15, to minimize

inductance and ground loops, the length of the leads

indicated by heavy lines should be kept as short as possible.

For best results, singlepoint grounding (as indicated) or

ground plane construction should be used.

On the other hand, the PCB area connected to the Pin 2

(emitter of the internal switch) of the LM2576 should be

kept to a minimum in order to minimize coupling to sensitive

circuitry.

Another sensitive part of the circuit is the feedback. It is

important to keep the sensitive feedback wiring short. To

assure this, physically locate the programming resistors near

to the regulator, when using the adjustable version of the

LM2576 regulator.

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

LM2576TV-12G

7.5 A SWITCHING REGULATOR, 63 kHz SWITCHING FREQ-MAX, PZFM5

LM2596-12MWC

7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC

LM2596-ADJMWC

7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC

LM2596-ADJMDC

7.5 A SWITCHING REGULATOR, 173 kHz SWITCHING FREQ-MAX, UUC

LM2601MDC

1-CHANNEL POWER SUPPLY SUPPORT CKT, UUC

LM2601MWC

1-CHANNEL POWER SUPPLY SUPPORT CKT, UUC

LM2636MTC/NOPB

SWITCHING CONTROLLER, 2000 kHz SWITCHING FREQ-MAX, PDSO20

LM2636M/NOPB

SWITCHING CONTROLLER, 2000 kHz SWITCHING FREQ-MAX, PDSO20

相关代理商/技术参数

LM2576D2TR4-3.3

功能描述:直流/直流开关调节器 3.3V 3A Buck PWM RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

LM2576D2TR4-3.3G

功能描述:直流/直流开关调节器 3.3V 3A Buck PWM RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

LM2576D2TR4-3.3G-CUT TAPE

制造商:ON 功能描述:LM2576 Series 40 V 3 A 52 kHz Step-Down Switching Regulator - D2PAK-5

LM2576D2TR4-5G

功能描述:直流/直流开关调节器 5V 3A Buck PWM RoHS:否 制造商:International Rectifier 最大输入电压:21 V 开关频率:1.5 MHz 输出电压:0.5 V to 0.86 V 输出电流:4 A 输出端数量: 最大工作温度: 安装风格:SMD/SMT 封装 / 箱体:PQFN 4 x 5

LM2576DP-12

制造商:HTC 制造商全称:HTC Korea TAEJIN Technology Co. 功能描述:3A, 52kHz, Step-Down Switching Regulator

LM2576DP-3.3

制造商:HTC 制造商全称:HTC Korea TAEJIN Technology Co. 功能描述:3A, 52kHz, Step-Down Switching Regulator

LM2576DP-5.0

制造商:HTC 制造商全称:HTC Korea TAEJIN Technology Co. 功能描述:3A, 52kHz, Step-Down Switching Regulator

LM2576DP-ADJ

制造商:HTC 制造商全称:HTC Korea TAEJIN Technology Co. 功能描述:3A, 52kHz, Step-Down Switching Regulator